Resistance spot welding (RSW) is a dominant joining method in automotive and aerospace manufacturing. A typical modern vehicle, for example, contains thousands of spot welds which experience a range of static, impact and fatigue loads over the life of the vehicle. The quality of these welds is inherently important to the durability and safety of the final automotive or aerospace structure – therefore routine strength testing of spot welds is a critical aspect of any RSW operation.

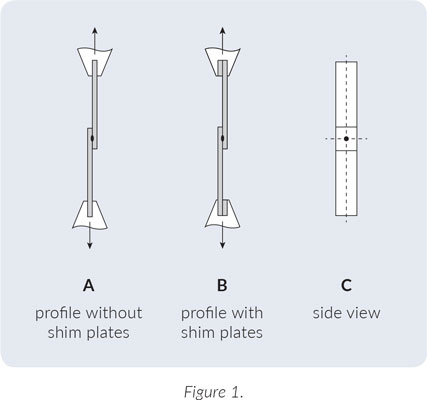

While a number of test methods have been evaluated for weldability and weld quality in RSW applications, the quasi-static, tensile lap-shear test is by far the most commonly used laboratory and at-line test method for determination of weld strength. The primary appeal of the tensile lap-shear test lies in its overall simplicity: simple sample preparation, simple testing method and easy interpretation of the results. Figure 1 shows the configuration of a typical tensile lap-shear sample for testing a single spot weld.

The critical dimensions of the test sample or ‘coupon’ are typically determined by the size of the weld nugget and vary among different international testing standards. It is important to have identified the proper testing standard for your industry (ie. aerospace, automotive) and range of application (ie. high-strength steels, aluminum, etc.) to ensure that your sample preparations and testing method conform to the proper standards for your industry.

Sample testing is accomplished by mounting the samples between clamps or ‘grips’ on a standard universal testing machine or ‘tensile tester’. Once mounted between the grips, the sample is pulled in tension at a constant rate of loading and the resulting force or ‘load’ applied to the lap- shear coupon is measured using an in-line force transducer.

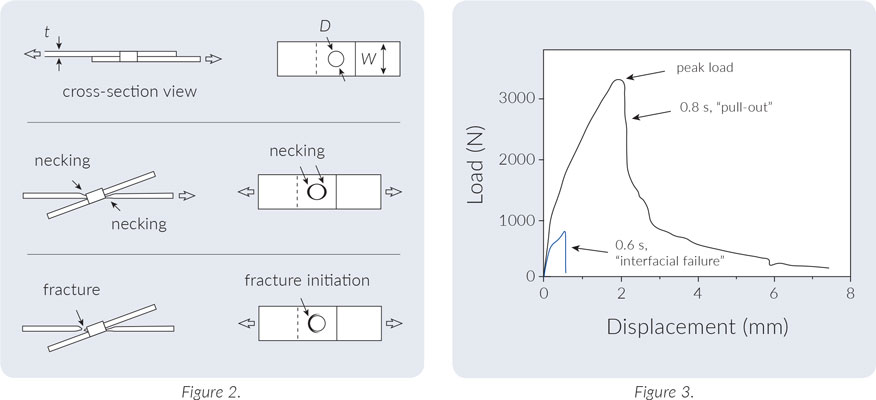

Good quality spot welds will display the progression to failure shown in Figure 2, where the failure at the nugget interface is referred to as ‘pull out’. However, a poor weld can result in an ‘interfacial failure’ – the differences in the load-to-failure results from lap-shear tensile testing provide clear detection of the quality of the weld as shown in Figure 3. The lap-shear tensile test has been proven over many years to provide excellent sensitivity to weld quality and has become a standard for RSW qualification across multiple industries.

RSW strength testing of the weld can be easily performed using a basic quasi-static, tensile testing system. In selecting an appropriate testing system, care should be taken to select a unit with a robust, high stiffness frame – for at-line quality testing, simple operator interfaces are preferred for ease of use and throughput. The United LCH ‘Speedy’ Testers are an excellent example of robust tensile testing option designed specifically for integration into manufacturing environments such as RSW testing.

For more information on the Speedy Tester or to review other materials testing technology, please email sales@unitedtesting.com.

Download Complete Spec Sheet